Our Sip Panels

Our Standard

Sip Panel Features

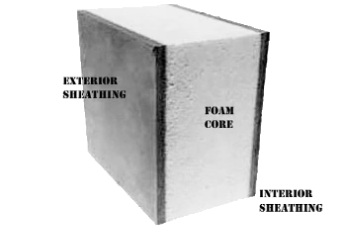

Forever Bilt has standardized on our manufacturing process using EPS Foam Cores and MGO Board as our Exterior and Interior Sheathing. We also have additional options for customization of panels. The below highlights show some of the exciting performance of our SIP Panels using MGO Board and EPS Cores.

Our Plants

Manufacturing process

Forever Bilt boasts a state-of-the-art manufacturing process for our SIP (Structural Insulated Panel) panels, this manufacturing process sets us apart in the construction industry. Our SIP panels are crafted using a cutting-edge technique that involves the application of closed-cell foam insulation and MGO (Magenesium Glass Oxide) board on both the interior and exterior surfaces of the panel. This meticulous construction method ensures exceptional thermal insulation properties and structural integrity, making the panels highly efficient and durable.

Our Forever Bilt’ SIP panels come with Florida Product Code approvals specifically tailored for high-velocity wind areas along the Florida coast. This certification demonstrates the panels’ ability to withstand extreme wind forces common in hurricane-prone regions, providing a reliable and resilient solution for building in challenging coastal environments.

Additionally, our SIP panels have undergone rigorous testing and have been approved to withstand wind speeds exceeding 230 miles per hour. This remarkable resilience showcases the high-quality construction and engineering standards upheld by Forever Bilt, offering customers confidence in the superior performance and durability of our SIP panel system.

Customizations

To get started with a custom or standard order please Get in Touch with us to discuss and go over your specific needs.

ESP ( STANDARD)

ESP ( STANDARD)

EPS is a lightweight, rigid, plastic foam insulation material produced from solid beads of polystyrene. It is widely used in various applications due to its unique properties.

Expanded Polystyrene Foam